Products

Zhejiang Double Arrow Rubber Co., Ltd.

Steel cord conveyor belts are suitable for high strength, long distance, and heavy load transportation of materials, which are widely used in coalmines, mines, ports, metallurgy, electricity, chemical industries, etc.

1. High tensile strength: The belts are suitable for large span, long distance transportation of materials.

2. Small elongation in use: The belts need only a very short take-up stroke distance.

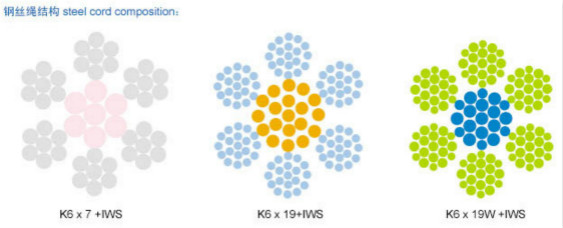

3. Small diameter of drive pulley: The carcass has a layer of longitudinally arranged steel cords as its skeleton,and thus is resistant to flex fatigue. Therefore, drive pulley of smaller diameter can be used to make the equipment smaller.

4. High adhesion between rubber and steel cord: The steel cords are coated with zinc on their surface, and also the rubber used has the property of good adhesion with steel cords. Therefore, the rubber is tightly adhered to the steel cords and is resistant to shock and difficult to drop, so the rubber belts are long in service life.

5. Even tension of steel cords: Out of our advanced techniques in manufacturing, the steel cords are very evenly arranged and have the same tension, so the belts are well balanced in running and difficult to run deviation.

6. Good troughability: As the carcass has no transverse skeleton, it is easy to form a deep trough, so the belts can load more materials and prevent the materials from escaping.

7. Good troughability: As the belt body has no transverse skeleton, it is easy to from a deep trough, so the belts can load more materials and prevent the materials from escaping.

8. Inspection of the belt with X-rays: Users can take X-rays to inspect damages of the skeleton steel cords on the conveyor machines to prevent accidents from happening.

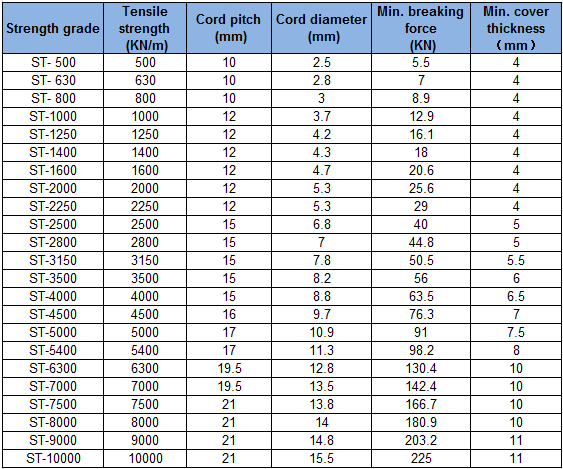

Note: Cover thickness, cord diameter, and cord pitch can be manufactured according to customer’s requirements.

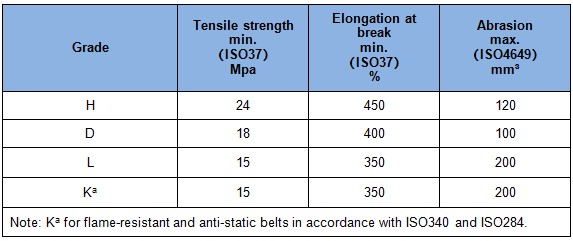

The values will help to determine the appropriate cover compound for the application or for the materials carries. Reliable assessment of the behavior of the covers in service for wear and cut resistance cannot be determined from tensile strength, and abrasion values alone.

浙公網(wǎng)安備33048302000315號(hào)

浙公網(wǎng)安備33048302000315號(hào)

Copyright ? 2017 DoubleArrow.Net All right reserved.